Protec™ Enamel

Protect your heater with first-class enamelling

Our high quality enameled elements ensure

your equipment goes the distance.

Corrosion Resistant

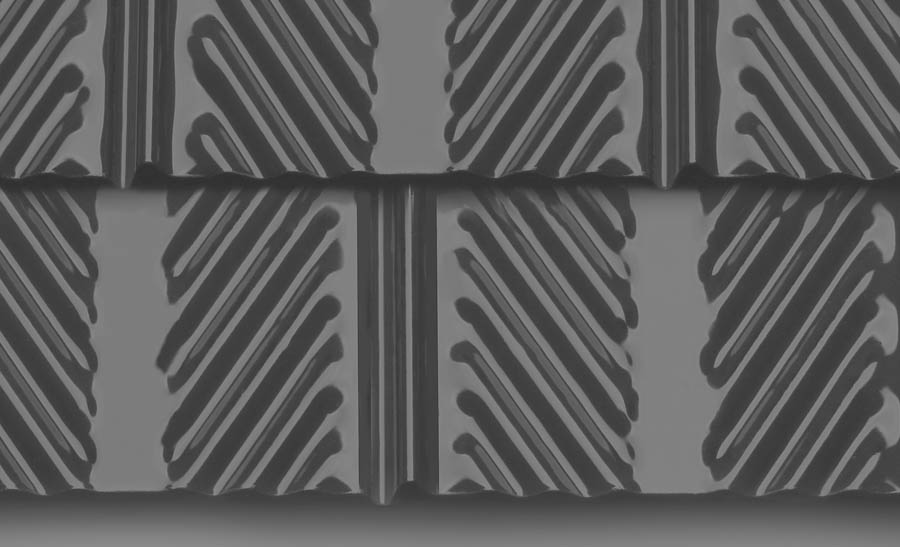

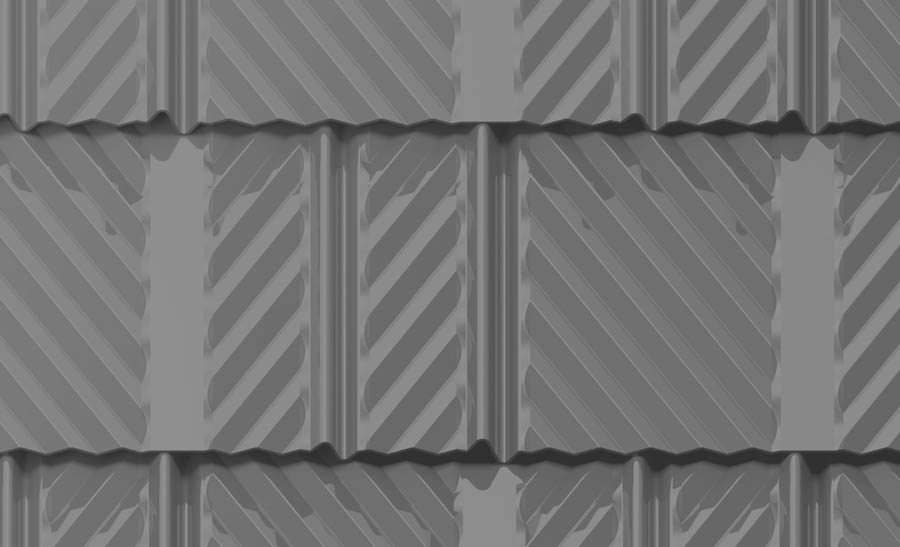

Thanks to years of research and field testing, our enamel is long-lasting and resistant to corrosion. Even after years of operation, elements utilizing our latest flow-coating technique show no signs of attack along the notch and undulation valleys.

High Quality Adhesion

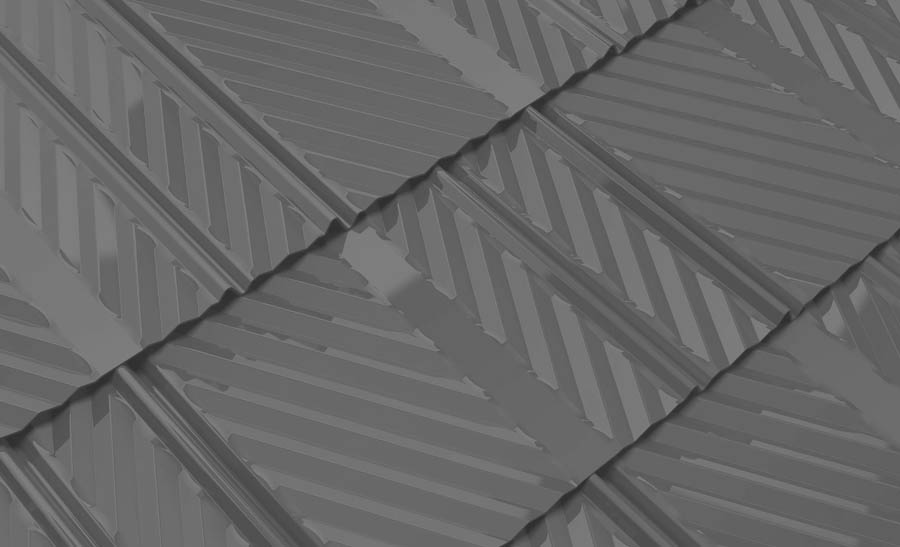

Adhesion of the enamel coating on the steel base material is essential for allowing sufficient packing pressure, and providing robustness to sootblowing and water washing. We achieve the highest adhesion grade A1 using optimized frit and slurry formulations, and a highly controlled firing process.

High Elasticity

Our enameled plates offer a superior and homogenous bubble structure resulting in a higher elasticity. High elasticity is essential for sufficient packing pressure when compressing the elements into containers.

Enamel Quality That Exceeds International Standards

We have over 55 years of global experience supplying enameled heating elements in regenerative heat exchangers, resulting in enamel quality that is renowned the world over.

Enamel For Our Industry

After extensive research and development, we concluded that the wet flow coating – or floating – method is the best method for applying enamel for our industry application. Our technique offers unparalleled results, exceeding international quality standards and providing an end product with superior operation lifetime.

Premium Materials and Processes. Premium Product

ProTec™ enameled heating elements are prepared with high-quality materials and meticulous processes to ensure the very best end product. The mill additives and bubble structure resulting from our enamel process give the end product unique ductility characteristics. This prevents cracks moving through the layer and also stops microcracks. Additionally, we apply consistent coating thickness, which is of the highest importance for the service life of enameled heating elements. Our flow coating process means we can provide an even coating thickness even in the critical zones of corrugations and undulations.

How ProTec™ Enamel Can Help Your Operations:

- Resistant to corrosion, for extended product life

- High chemical resistance against aggressive flue gas components including acid, water, and water vapor

- No need for pretreatment other than degreasing of the steel by rinsing it with hot water containing detergents

- Resistant to temperatures up to 400 degrees Celsius

- Superior and homogenous bubble structure

- High elasticity and adhesion onto the profiled elements to allow for sufficient packing pressure